The whole industry is changing. Artificial intelligence and Industry 4.0 are no longer utopic ideas for a distant future, they are already installed in several companies. With them, things we used to do also need to be reevaluated. There are new challenges and opportunities at hand. Maintenance teams cannot keep doing just the same old things. Maintenance leadership must be able to create an environment of continuous improvement and change, without compromising fundamental tasks and good practices.

To achieve sustainability, every business needs to reinvent itself from time to time. Change is necessary. However, change is also difficult and challenging. People tend to resist new things (finding all sort of justifications) and, for whatever reason, this is very accentuated in Maintenance.

So, why do we need to keep changing? What do we want to achieve with Maintenance anyway? For me, maintenance purpose is to ensure all critical equipment are running properly at the lowest sustainable cost possible. The maintenance culture must be aligned with this motto. Process and behaviors should be oriented to avoid breakdowns and unplanned downtime on any critical machine. Whatever we use today, the most advanced technologies, the current best equipment will all become outdated and even obsolete in the near future. So, the same way we need to maintain our assets, we need to maintain our people, processes, and culture to take advantage of new opportunities to improve.

New technologies, used properly, can help us to achieve better efficiency out of maintenance but, without a proper culture and environment of change, they may fail.

Are we acknowledging and rewarding the right behaviors in Maintenance?

1. What is the current culture we are fostering? Are we encouraging the best behaviors?

2. Let’s do a quick check. In the past month, who did you praise most: the people that fire fought a breakdown or the people who avoided breakdowns from happening?

3. How many times did you compliment a maintenance guy for fixing a breakdown? How many times did you compliment somebody for not letting a machine break?

It doesn’t matter much what we write in procedures and routines. If we do not reinforce and recognize the right behaviors, people will just stop doing it.

Likewise, how many times our maintenance guys taught operators on how to use machines properly to avoid breakdowns? If operators do not damage machines, maintenance doesn’t need to fix them. It’s one of the easiest low hanging fruits.

The more we (maintenance) interact with operators, by helping them to operate machines better, the more response on early issues we get (different noises, strange vibrations, high temperature, etc). Are we also reinforcing this kind of behavior?

What got us here, may not get us there

We cannot capture the full benefit of new technologies if we are still firefighting issues on the shop floor. Our first target should be minimizing unplanned downtime and after that reducing the planned downtime (yes, normally we can also do much better at it). Improving unplanned downtime has nothing to do with fixing things faster. There’s no sense in getting better at something that should not be done at all. We should avoid breakdowns, especially on critical equipment. But don’t stop there, small stoppages and speed losses also tend to account for significantly improving opportunities.

Next, we need to go after the planned downtime. Time-based preventive routines are actually not much better than running to failure in terms of costs. Several studies produced similar results; 80 - 88% of the spare parts normally replaced in such routines did not show signs of tear and wear that justified the replacement. It means, money thrown away. To make it worse, in most cases, PMs doesn’t avoid breakdowns either. So, we spend money to replace parts that were not yet bad, to try to avoid problems that will keep happening because we not acting in the right places… It gets even worse, some people instead of reviewing the PM process itself opt for reducing the time between preventives, adding even more costs to the business. Don’t forget cleaning and change-overs, if not done properly may lead to equipment issues and breakdowns.

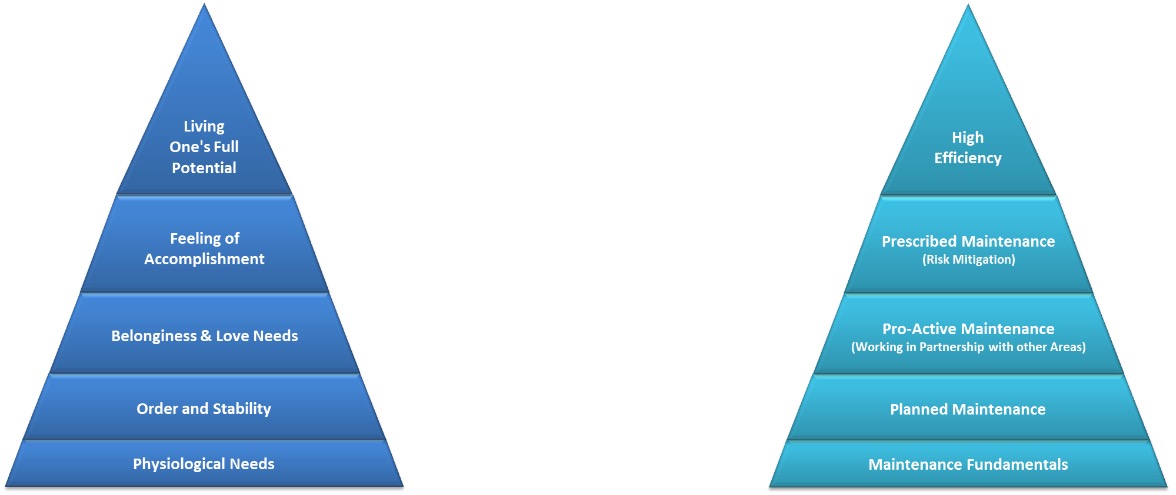

For critical equipment, we need something better. We need efficiency. If we list all the things we need to do to achieve a high-efficiency level, we can see the need to install some process to be able to create the base for another more advanced or sophisticated process. There’s a kind of optimal order for doing things in maintenance. If we put all in order, we will get something that resembles a pyramid.

The behavior improvement is part of what I call “pro-active” level, but this is the third level. The first level, “fundamentals”, most of the time, unfortunately, leave us in a firefighting mode. However, we need to build those fundamentals; we just can’t stop there. The following level is “planned maintenance”. Things start to get better at the “pro-active” level where we should be doing continuous improvement, root cause analysis (RCA), fault elimination, reliability studies and so on. But guess what, we can do better still. I will get back to this later.

We, as leaders, need to push implementations and take people by their hands until they reach a point they can do improvements by themselves. Firefighting and time-based preventive routines are way below of what we can achieve in maintenance. Current budgets and quality requirements entail us to do much better. And better, in this case, is possible.

Nowadays having good technicians is just a small part of what we need. We need to create teams with both diversity and participation to achieve a collective intelligence which will be bigger than the sum of the parts. The behavior of the leaders is instrumental to foster this kind of team. Capable teams will take ownership for the right tools and processes to improve and sustain high-level results.

New technologies

New technologies, used properly, can open new options. Artificial Intelligence, for example, is very promising. Like other processes, we need good and reliable data to apply Machine Learning. Data can come from sensors (on-line monitoring/CBM). The usage of AI and neural networks can help us to predict failures and improve maintenance that would be very hard to do with just standard sensors (especially when the failure is a result of a combination of factors). Augmented Reality is another example, we can improve the efficiency of changeovers (leading to fewer errors which impact both in quality and availability). Using those new technologies, we can free time from technicians to do more added value activities and, of course, minimize costs.

As Einstein said, insanity is doing the same thing over and over again and expecting different results. So, it’s time to review old concepts and aim for high efficiency at maintenance.

How to convince the team that they need to think and work differently than we have in the past?

As I said before, it is common to have resistance to change, especially in the maintenance area. It doesn’t matter our current state, we can be using the top technologies and state-of-the-art equipment or outdated machines. Sooner or later even newer technologies, materials or production methods will become available leaving our practices and equipment obsolete. We need to have in place a continuous improvement mentality, so implementing new changes will be part of the routine and we will keep up with whatever happens. Continuous Improvement is an enabler of change, but it needs to be done by the entire team (not a person or group). Every technician in the shop floor must do root cause analysis (with support if needed) and think about how to prevent failures or how to improve machines to avoid risks.

The new processes and technologies must help people to work better. We want the teams working smarter, not harder. Here again, new technologies can help a lot doing the repetitive work better than a human could, freeing time for creativity, innovation and other more added value activities (RCAs, FMEAs, reliability studies and so on).

New processes and technologies should be implemented in such a way that people understand the value-added of the new things and they cannot see themselves working again in old ways, otherwise, there will be a risk to fall back to the previous stage (if it's comfortable to go back, people will do it).

What is our goal anyway?

As I said in the beginning, maintenance purpose should be to ensure all critical equipment are running properly at the lowest sustainable cost possible. It means we know and have internal alignment about the most critical equipment. We need the best process and techniques in place, not to fix or firefight, but to make sure equipment are running properly at high efficiency: no breakdowns, no unplanned downtime. As a consequence, we can achieve an optimal cost.

The optimal cost will be a combination of factors. Spare parts are one of the biggest costs, but often not taken in the right account. If a spare part is not lasting as much as we need, another alternative is required. Today there are plenty of possibilities using new production methods and materials. But we need to look at alternatives focusing on the Total Cost of Ownership (TCO). Good spare parts, with the right design and materials that last longer (and so minimize replacement and all its related costs), will help to achieve the optimal cost.

It doesn’t work the other way around. We cannot cut the maintenance budget and expect better results. But we can install the right tools, the best processes, and techniques, ensure discipline and safety. This combination will naturally lead to better results and lower costs.

Where should we start?

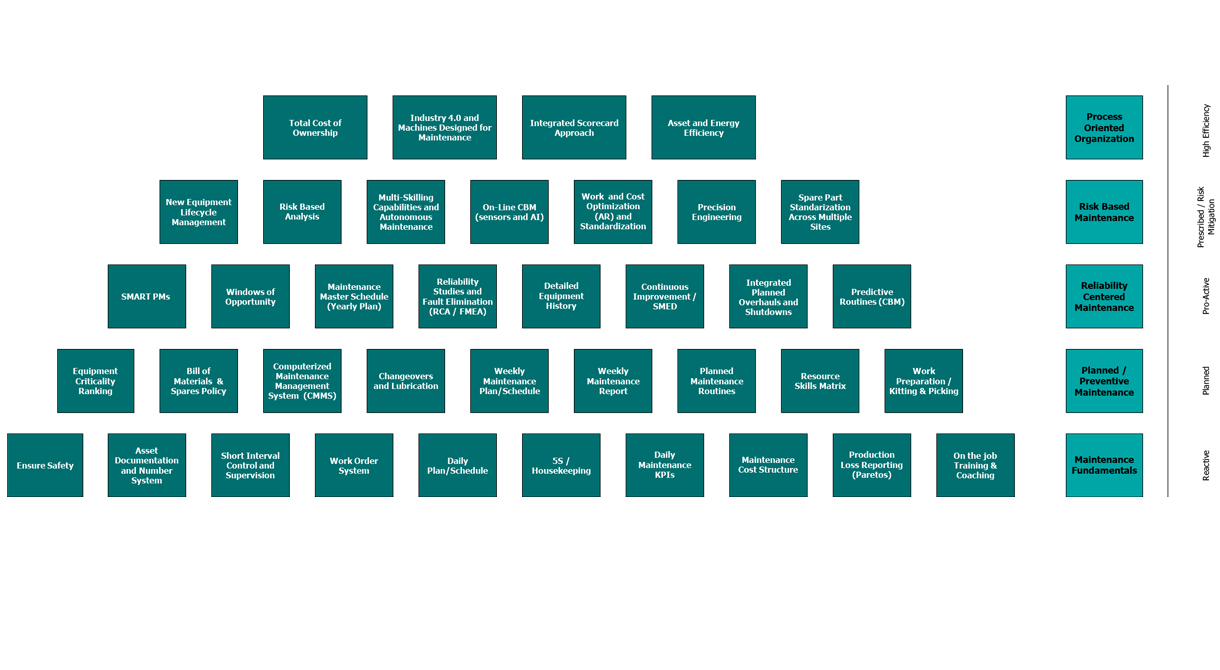

As we roll out new initiatives and implement new technologies, we need to keep doing some fundamental things. Things will not work at an optimal level when those fundamentals are not properly in place. Something similar to the Maslow’s pyramid of needs: We cannot live in the higher levels if the lower ones are not fulfilled. Making an analogy and transporting the psychology concepts to maintenance, we would have something like the picture below.

We need to have the fundamentals (safety, work orders, daily plans, 5S/housekeeping, etc) to start doing planned maintenance. We need that to move to a pro-active level and so on until we reach a high-efficiency level. So, we need to start at the base of the pyramid: fundamentals. Maintenance results will improve each level we climb until we reach the high-efficiency level (high reliability and lowest sustainable cost).

The maintenance pyramid

Adding more details, the picture would look like this one:

We all want to be at the top, on the high-efficiency level, but we need to master the other levels first. We cannot stop doing the lower levels to aim higher. If something goes wrong on the lower levels things go south like Maslow states.

In my point of view, maintenance should start in early stages of a new project, so we can optimize a project looking through the maintenance point of view (Industry 4.0, machines designed for maintenance, asset efficiency, maximize synergies, parts standardizations, right materials, proper design, machine loads, easy access, poka yokes, energy efficiency and so on). But we also need to ensure safety, an efficient work order system, a daily schedule, a monthly plan, on the job training, etc. We cannot focus on optimizations when equipment are constantly breaking.

There’s no magic here. The lowest sustainable cost will be the total cost of keeping the discipline of carrying out the right routines to maintain the machines running properly.

Do we need to install all those processes and controls? It depends on the results you want to achieve from the Maintenance area.

Keeping the discipline costs money. There’s a limit some parts can run. Not keeping the discipline costs, even more, it falls back to the reactive mode (correctives), accelerates equipment deterioration and brings higher costs for either overhauls or asset replacements. So, the choice is yours. Choose wisely.

(by Eduardo Schumann, Improving efficiency consultant)

(by Eduardo Schumann, Improving efficiency consultant)