In order to keep its relevance to get a share of the pie, Food industry needs to adjust to the constant changing consumers’ habits. The range of the options are bigger than ever: organic x non organic, more natural ingredients (free range eggs, no colorants, less sugar and salt, etc), packaging convenience x sustainability, fresh x shelf life, etc. Not to mention good quality. Some of those options comes with an added price tag, something that most of the consumers are not willing to pay. So, how to solve this gridlock?

Moving out of the pack

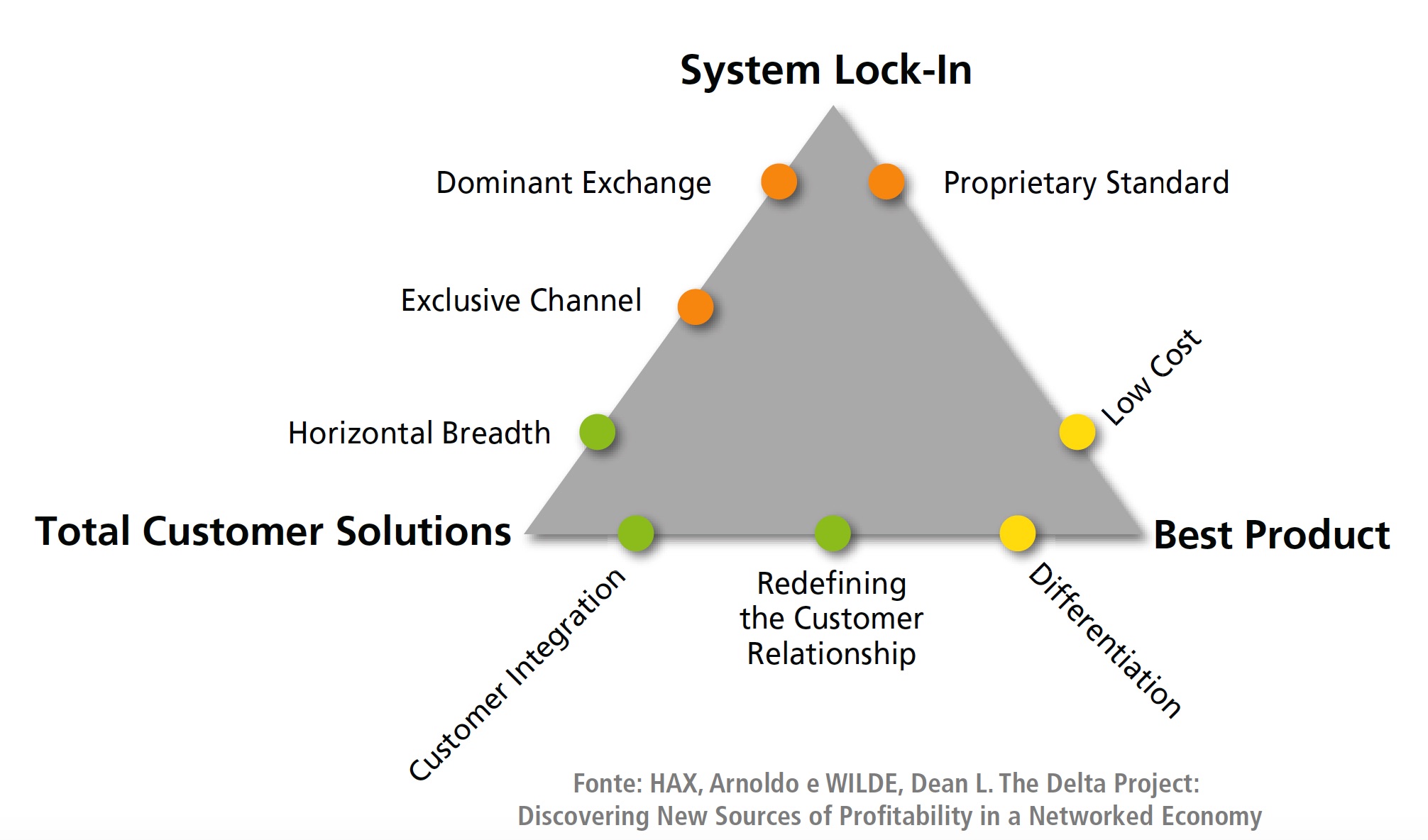

According to Michael Porter, strategy is about making choices, trade-offs; it's about deliberately choosing to be different. This approach is also confirmed by Arnoldo Hax, when looking to generic transactions (mostly of B2C) we either need to have the lowest cost or a differentiation. If you have no product differentiation, the best price will tend to win (to reduce price we often need to give up on margin damaging the company economics). In this case, the company with the best cost will probably survive at least another round.

Having competitors is already challenging, but the biggest threat of an established food product is often a “new” product (that can be a variation of an existing one). Products with a legion of adepts and good market share are constantly threatened by new launches. Even with a good brand loyalty, consumers will probably try the new products because the risk of trying something new is basically its price tag (it’s not like buying a car or an appliance). Of course, the real impact of a product should be measured after the end of the promotions, normally associated to new product releases, or when it’s no longer a new product. For the industry, constantly releasing new products requires some flexibility in the processing and packaging lines.

The Heinz tomato ketchup is a good example of a product that have been outliving the competition. Introduced in 1876, it still ranks high in consumer preference. To keep its relevance for so long it (.) found a good balance in the product that cannot be easily imitated by other companies. In this case, the “secret” is in the ripped tomatoes that creates most of the consistency of the ketchup. Without them, starch is needed and with it probably some sort of colorant and stabilizing agents should be also necessary. With those added chemicals, it will no longer be as natural as the original. Especially today, having a more natural product seems to be a good choice, despite an old recipe.

Manufacturing Efficiency

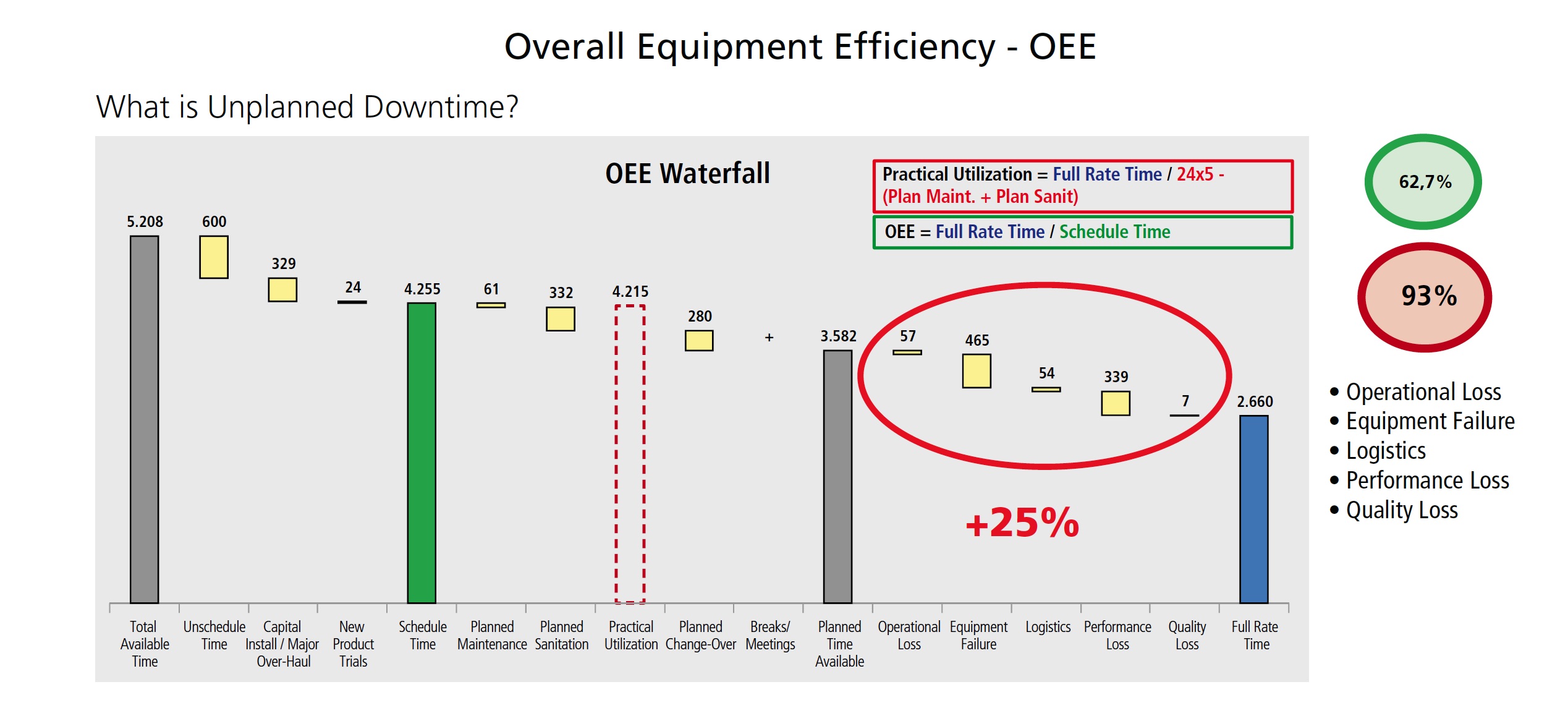

One of the challenges we face in food production is to find a proper balance between productivity and flexibility. To minimize costs we need high equipment efficiency and specialization. In the other hand, we know things will change, so we need some flexibility to modify recipes and bottle/can sizes. Flexibility comes with a cost. All the time we are doing change overs, setups and adjustments in the machines we are not producing and that will add to our manufacturing costs.

Machines must be designed with interchangeable parts, “poka yokes” and other SMED (SMED = Single Minute Exchange of Dies, from the Toyota Production System) principles from the beginning. Cleaning and sanitation must be considered as part of the production process. Improvements on those aspects will reduce planned downtime and improve equipment efficiency.

With the years of experience dealing with production lines the biggest improvement opportunity, in my opinion, still remains in the unplanned downtime. Unplanned downtime is the combination of the following elements: Operational Loss, Equipment Failure, Internal Logistics, Performance Loss and Quality Loss. It’s not hard to find lines with opportunities greater than 25%. The biggest problem here is that often people are already used to it, they became the “normal”, so they don’t challenge those numbers any more. Micro stoppages are often not even measured. As Peter Drucker said, “If you can't measure it, you can't improve it”. Measuring and dealing with those stoppages is one of the first things (to) do. Improving unplanned downtime increases asset utilization, improves efficiency and reduces costs.

As a sub-product of improving efficiency we tend to reduce yield losses caused by breakdowns. Unfortunately, several lines were designed not taking the proper account of how much we lose in yield with scrap, change overs, cleaning/sanitation and overfill.

Precision engineering and the proper maintenance tools (like laser alignment) are essential not only to minimize spare parts wear and tear but also to reduce energy consumption (the level of precision required cannot be achieved by naked eye). Under dimensioned motors are cause of breakdowns, over dimensioned are waste of energy. Air compressor leakages are often wasting an expensive energy. The good news is this can be improved. On top of this, new technologies can help us save energy on existing equipment better modulating the electricity flows.

Maintenance is often part of the problem, but it doesn’t need to be. If we base our maintenance routines on corrective and fixed time preventive procedures, we will be doomed to fail. Good maintenance is the key to improve all the other unplanned downtimes. A robust root cause analysis is essential to create a continuous improvement mentality. Together with predictive maintenance, can boost production results and bring costs down (and this will be the topic of my next article).

Good Quality Matter

If you think quality (there are many different definitions for quality. For this analysis we are using the conformity to specification) may be expensive, try out the cost of the lack of it. Right first time may cost something, but rework tend to cost more and it’s often a “hidden” cost as often is not properly considered as something that could be avoided from the beginning. Quality conformity needs a solid process and that adds steps and controls to the production (adding costs as well), but a recall costs much much more, not to mention the damages to the brand.

Do it Safely

Whatever we do in the shop floor needs to be done safely. Workers perform better in a safe environment. Any stoppage caused by an accident add a lot of downtime. So make sure all the machines and process are as safe as possible so we have no accidents at all. Add fail proof device in any point a mistake may cause an accident or break an equipment (if operators don’t break, maintenance doesn’t needs to fix it, this is always a low hanging fruit). We can never relax the attention here, any new risk must be deal with.

About everything impacts in the cost, but as mentioned before quality costs, but lack of quality is even more expensive. Same is valid for safety, maintenance, logistics and planning. So, doing the right things will tend to put costs under control. Of course, we need to be constant looking for new ways to improve efficiencies and reducing cost. The trick here is to find a proper balance in terms of differentiation to be attractive and relevant for the customers, while not trying to get short cuts. Keeping the discipline of doing the right thing over and over seems to me the best way for sustainable results.

(by Eduardo Schumann, Improving efficiency consultant)