Although the authorities are more focused on product quality than energy consumption, some recent initiatives regarding faster and more flexible processes for approvals have an environmental side-effect. And although energy didn’t necessarily drive this change, it still reduces cost and has a positive environmental impact. Cleaning consumes the most energy and water in pharma manufacturing. From vials and bottles to vessels, pipes and equipment, more than 2/3 of water consumption in manufacturing facilities is related directly to cleaning.

A large number of pharma companies are looking into water consumption optimisation by using the reduction and recovery strategy. Some of the waste water from a pharma manufacturing facility is much cleaner than the water going into the facility – such as the final rinse of equipment with purified water. Therefore, it makes sense to salvage some of this and use it to reduce the amount you need to treat and put back into the external environment, and you also reduce water intake.

New innovations in CIP technology can improve water consumption throughout the various steps of the cleaning cycle. Energy and water quantity usage varies depending on the process. Very few manufacturers have put tools in place that render the CIP process efficient. Aim of this paper is to review key elements of how to improve CIP water consumption performance through operational efficiency, process design and advanced automation.

When a CIP process is in operation, production uptime is stopped but luckily more advanced CIP automation enables dramatic reductions in trouble-shooting time in the event of a problem, cutting what once took hours to perform into minutes of diagnostics. An optimized CIP process can reduce cleaning times by up to 20%. For example if CIP currently takes around 5 hours of each day, a 20% reduction in cleaning time will deliver approximately an extra hour of production time to each day.

The amount of water and chemicals used can also be reduced by introducing recovery systems so that the liquid can be reused instead of sent down to the drain. New chemicals can be experimented, cleaning times variation, adjusting water temperature, reconfiguring settings, maximizing chemical effectiveness, implementing eco-friendly solutions. In addition, installing flowmeters on inlet and outlet pipes can be done to verify the volume of liquid sent and received.

This can be analysed to identify any unusual losses through the leak chamber of the valve.

An efficient cleaning recipe is based on four key parameters (sometimes referred to as “The 4 T rule”). The process automation system monitors and verifies these four fundamental parameters for an optimal combination and so a dramatic reduction in costs.

The four “Ts” are defined as follows:

• Time – duration of the cleaning cycles.

• Temperature – the temperature of the cleaning products.

• Titer – the concentration of the cleaning products.

• Turbulence – the speed, pressure and impact of liquids projected by cleaning products that need to be generated to perform the cleaning task.

A final check can be made following the last rinse. The software will indicate a “remaining conductivity” measurement. If this number is high then it means that the final rinse was not well done and that some chemicals are still present in the pipe work.

A case study

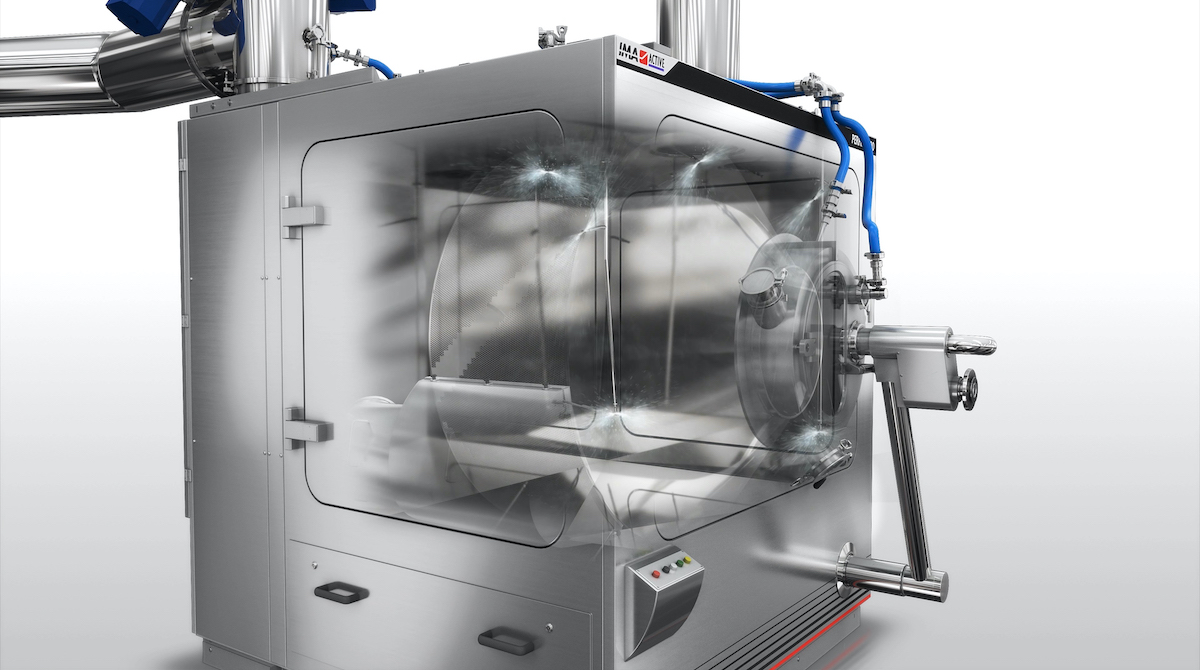

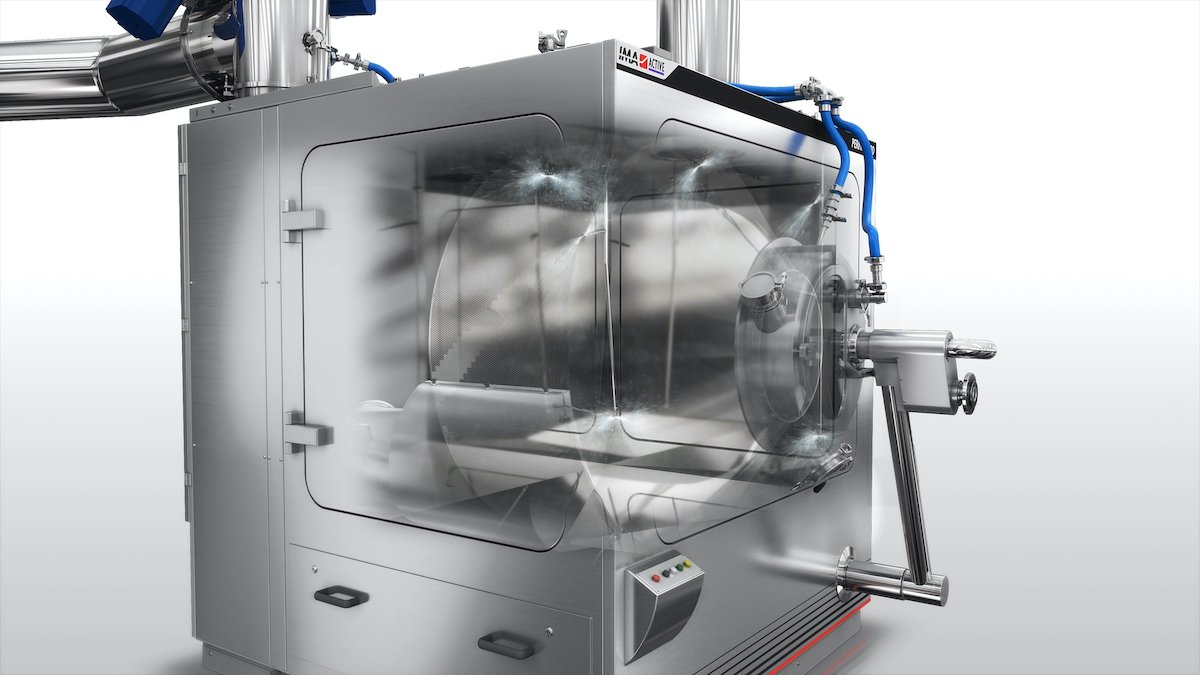

In the following case study, it will be described an exercise done on a coating machine to optimise the use of rinsing water.

Equipment: the equipment that has to be cleaned is a PERFIMA 200 perforated coater (IMA, Italy) providing a perforated drum of 250 L, 4 spray guns for the coating dispersion, and external cabinet to fit the drum and inlet/outlet air ducts. The machine is provided with a CIP system with spray ball and cleaning lances directed in all the areas that have to be cleaned after a process.

Hydrowash washing skid properly supplies the PERFIMA CIP system selecting the desired water type for each phase (up to 3 water inlets - tap, softened/demi or purified), controlling the water temperature with an in-line water heat exchanger and dosing the detergent (up to 3 detergents) with an automatic in-line detergent dosing system.

Temperature and detergent in-line control systems have significant advantages in terms of costs and energy/detergent saving avoiding the use of heated water or prediluted water/detergent mix storage tanks. PERFIMA CIP lines is designed with balanced water flow rates in order to optimize the regulation of these in-line control systems. In addition, heated compressed air is blown at the end of washing phases to drain and dry the CIP lines to avoid cross contamination and hygienic risks.

PERFIMA CIP includes washing lines designed to cover all the coater internal surfaces and a recirculation system connected to the wastewater main discharge. The operator can select for each washing recipe phase to perform either a “go through” or recirculation washing option.

The washing lines, mentioned in the recipe tables, are connected to a manifold placed on the coater roof and split as follows:

- Line I1:

o Front and rear rotating lances inside the drum

o 1 x rotating nozzle on the front door

o 1 x rotating nozzle on air outlet isolating valve

- Line O1

o 2 x rotating nozzles on left side of the cabinet

o 1 x rotating nozzle on top side of the cabinet

- Line O2

o 2 x rotating nozzles on right side of the cabinet

o 1 x rotating nozzle on air inlet isolating valve

- Line O3

o 2 x rotating nozzles inside the outlet air conveyor

o 1 x rotating nozzle above the outlet air conveyor

- Line O4

o 1 x rotating nozzle on air outlet pipe

o 2 x rotating nozzles below the outlet air conveyor

- Line O5

o 3 x rotating nozzles on left side of the cabinet

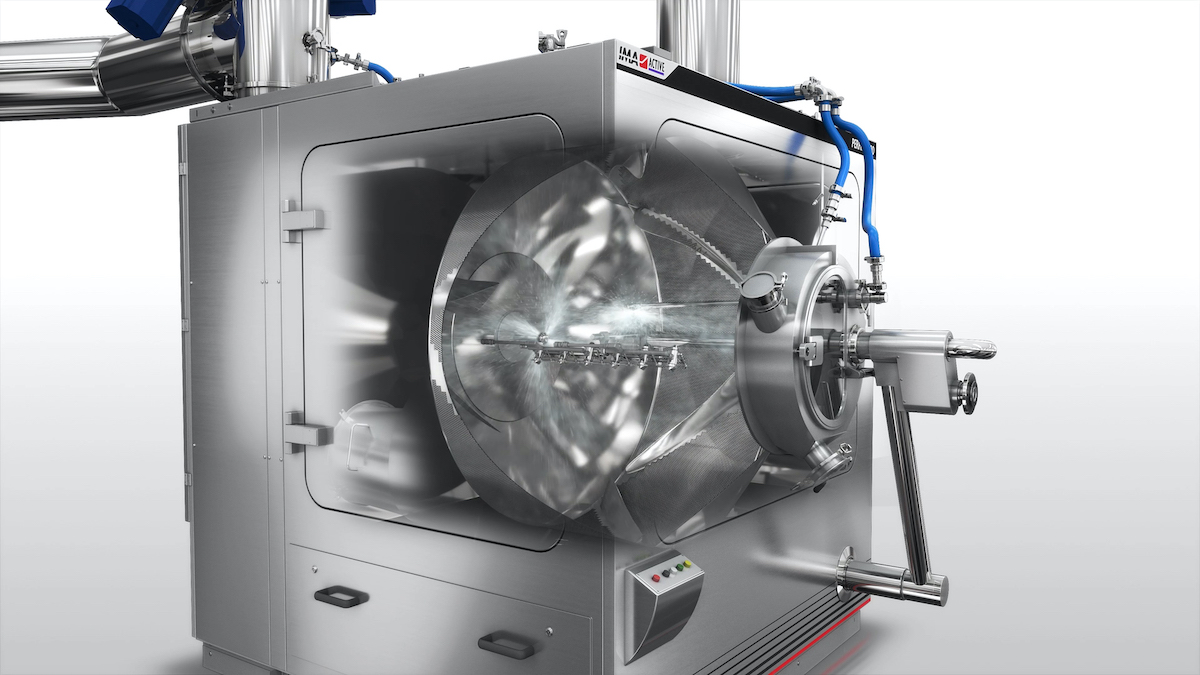

Figures from thirth to sixth show some virtual representations and real details of the washing line described above.

Figure 3-3D model with detail of washing line I1: front rotating lance and front door rotating nozzle inside the drum

Figure 4-Detail of washing line I1: front rotating lance and front door rotating nozzle inside the drum

Figure 5 – 3D model with details of “O” lines: rotating nozzle inside the PERFIMA cabinet

Figure 6 – detail of “O” lines: rotating nozzle inside the PERFIMA cabinet

Contamination Procedure

To better mimic an industrial case study the coater was contaminated using 150 kg of placebo tablets coated with Opadry 85F Pink (prepared at 20% concentration in water) for a theoretical 3% weight increase of the cores. This resulted in a 45 min spray time process that was replicated 10 times in order to simulate an industrial production properly.

The contamination level of the equipment after 10 runs was anyway not critical due the new mixing system in the coater providing optimal coating distribution and minimal coating losses.

CIP Standard Recipe

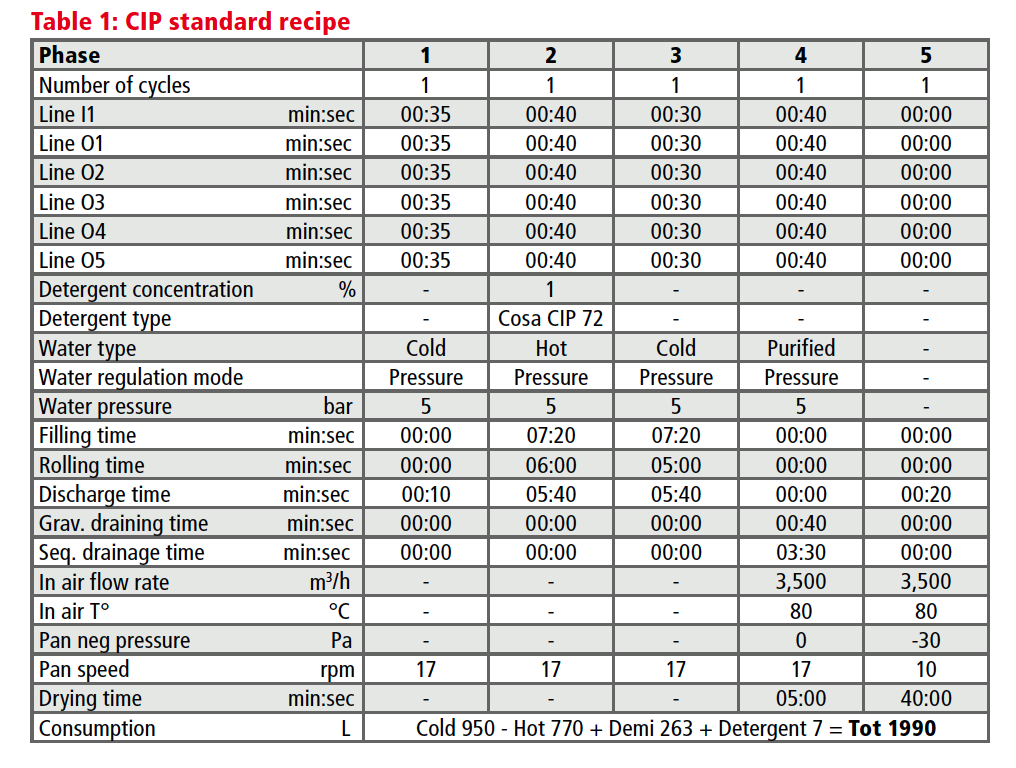

To create a good comparison a standard CIP as reference recipe was performed after contamination procedure with the parameters showed in table 1.

Recipe Providing Recirculation

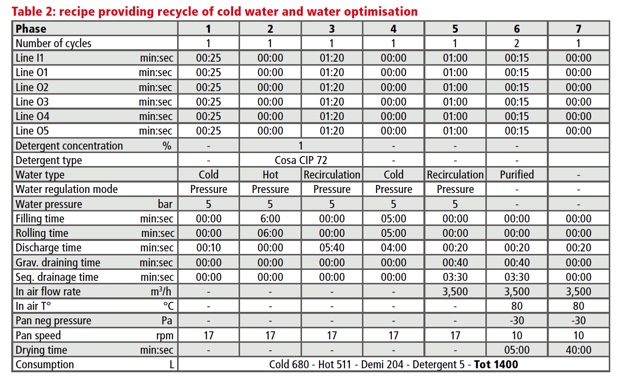

The strategy to decrease the water consumption aimed to re-use part of the water using the recipe below.

In both phase 2 and 4 water is accumulated in the coater using the filling time, using the drum cabinet as a reservoir: this water, after its use, is then re-used in phase 3 and 5 respectively and good saving is obtained.

Another optimisation consisted in improving the rinsing phase with purified water splitting the phase in 2 cycles and decreasing the total time of water delivery (and amount). Literature reports that one cycle providing longer contact time and water delivery offers less improvement in rinse effectiveness compared to more and shorter cycles with lower contact time and water delivery.

Final Results and Conclusion

In both set of tests the final result of CIP was very good in terms of visual inspection and water conductivity: target of 4 μS was achieved at the end of rinsing step.

Recipe optimisation obtained by minor changes in of water time and mainly the use of recycling procedure led to a total water saving of 590 L equivalent to a 30% water reduction compared to initial total water recipe. Detergent quantity was also reduced by 30%.

References

1) Water efficiency and safe re-use of different grades of water - Topical issues for the pharmaceutical industry - Elina Stradea,b, Daina Kalninaa,*, Joanna Kulczyckac aRiga Technical University, Faculty of Materials Science and Applied Chemistry, Institute of General Chemical Engineering, Paula Valdena iela 3/7, Riga, LV-1048, Latvia bJSC “Grindeks”, Krustpils iela 53, Riga, LV-1057, Latvia cMineral and Energy Economy Research Institute, J.Wybickiego 7A, Krakow, Poland

Water Resources and Industry, Volume 24, December 2020, 100132

2) A new water management strategy for the pharmaceutical industry.

https://www.a3p.org/it/a-new-water-management-strategy-for-the-pharmaceutical-industry/

3) How to Optimize Clean-in-Place (CIP) Processes in Food and Beverage Operations - Benjamin Jude and Eric Lemaire, Schneider Electric White Paper.

4) Water, Energy Conservation in the Pharmaceutical Industry, https://www.watertechonline.com/home/article/14170505/water-energy-conservation-in-the-pharmaceutical-industry, Michael Costello, Jan 1st, 2010

5) Validation of the Cleaning in Place of the coating pan PERFIMA, IMA

https://ima.it/pharma/paper/validation-of-the-cleaning-in-place-of-the-coating-pan-perfima-ima

6) Effectiveness of Rinse Water during In-Place Cleaning of Stainless Steel Pipe Lines

Mengyuan Fan 1, David M Phinney 1, Dennis R Heldman 1, J Food Sci. 2015 July