IMA Coffee Hub will be at World of Coffee 2022 in Milan to present the latest news for coffee processing and packaging. A unique global supplier, capable of offering specific technical solutions along every step of coffee processing, from green coffee reception systems to packaging in stand-up pouches, capsules, paper pods, paper cases of various shapes and sizes, and the end of line.

A new model of Specialty Roaster TT 5/10, the Petroncini roasting machine that roasts from 3 to 10kg per batch, is set to go on display at World of Coffee in Milan at the stand MS-H10 of IMA Coffee. Compact and easy to install, thanks to its single-phase power system, the new TT5/10 has been designed for small specialty roasteries and for coffee research and training centres. Thanks to heat control, roasting air volume and the drum rotation speed, this roasting machine can in fact let you vary the method of transferring heat to the bean, achieving a perfect balance between convection and conduction, according to the desired end product. We can thus succeed in achieving countless sensory profiles, developing the coffee’s deepest aromas, from light roasting to the very darkest. The TT5/10 is actually equipped with two independent suction systems, one for roasting and one for cooling, so that the two phases can be carried out simultaneously and in full capacity between one batch and another, without neglecting the cooling phase.

The thermal energy cycle adopted by the Specialty Roasters allows for the direct and gentle drying and caramelisation of the coffee sugars, putting the source of heat not in direct contact with the roasting chamber, in order to be able to control the amount of heat transferred to the bean and reduce uncontrollable thermal inertia as much as possible. Having good thermal insulation of the external surfaces is an added value which these machines have been able to boast for almost 100 years now. The new software Maestro gives the roast master the chance to choose either the complete freedom of roasting or the pre-setting the different desired roasting profiles.

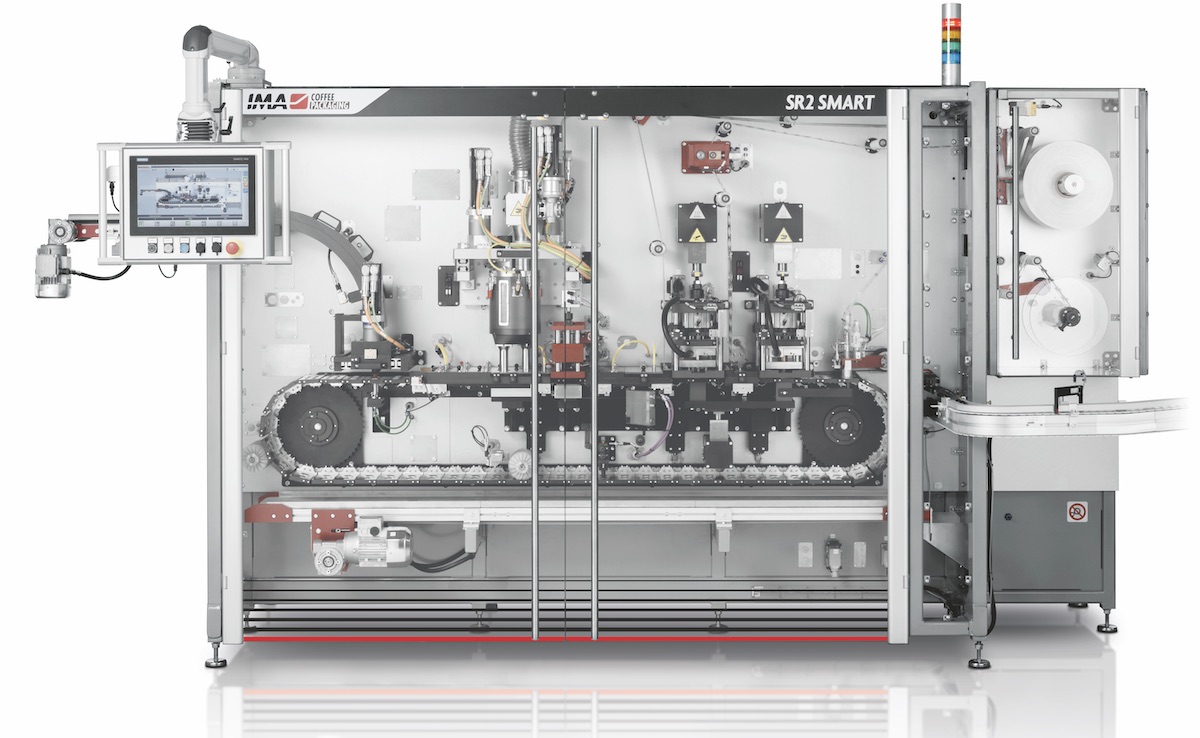

Many innovations for the world of packaging will be presented, starting from the new solutions for vertical packaging, to capsule filling machines specially designed for specialty coffees, up to new projects for sustainable packaging. Among the new leading technologies of IMA Coffee Packaging, the SR SMART Series, capsule filling and sealing machine, and the C-900, high speed capsule cartoning machine.

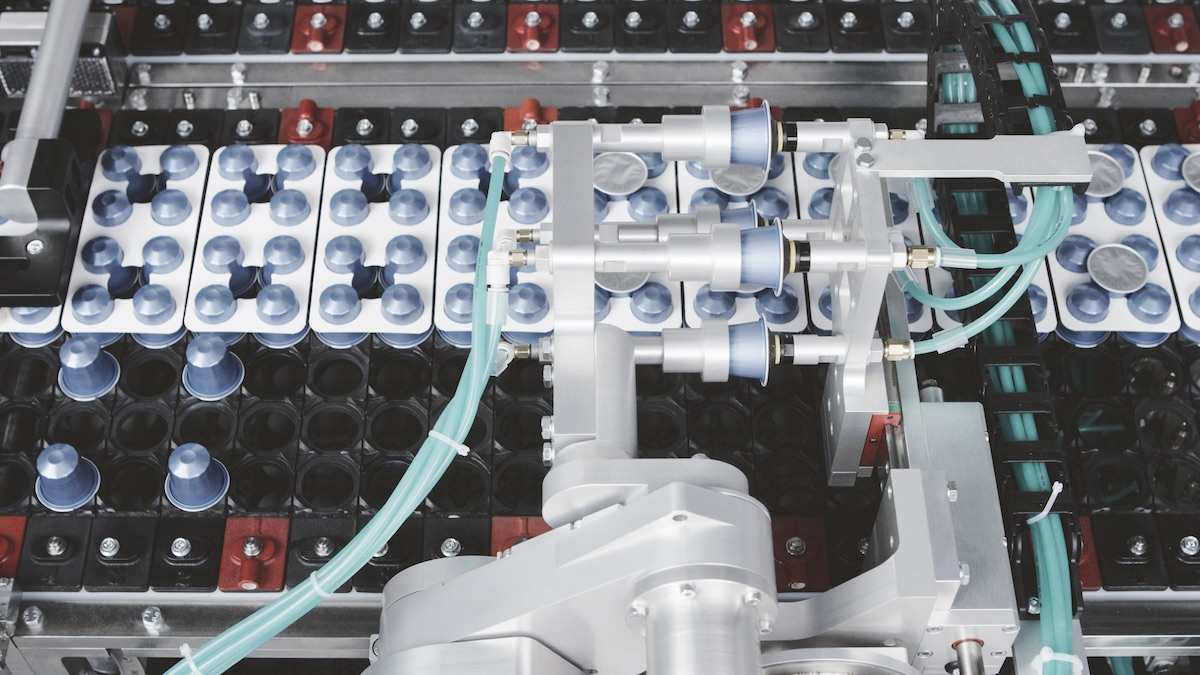

With a capacity ranging from 60 to 120 capsules per minute, the SR SMART Series is the the solution for small and medium capsule productions, capable of handling any type of capsule in plastic, aluminium, and compostable material. The capsules can be sealed with aluminium film, microperforated, filter paper, triplex laminate, PP and compostable lid. Filters and diaphragms can be inserted into the capsules and on their bottom. Combined with high-speed capsule filling machines, C-900 can pack capsules in a wide range of sizes and different carton configurations, allowing the insertion of interlayers and/or inlays according to customers’ requirements and ensuring capsule stability and integrity.