International markets, though dealing with today’s complex economic situation, recognize the value of the innovation patented twenty years ago by Cassoli Group and still a focus of research to improve its usability.

In Italy, the TopSyl system for covering can tops has not caught on, however. Jacopo Cassoli, general manager of Ecocap’s, commented on the reasons for this just after the trade fair Drinktec, where the company presented the latest evolution of Topsyl.

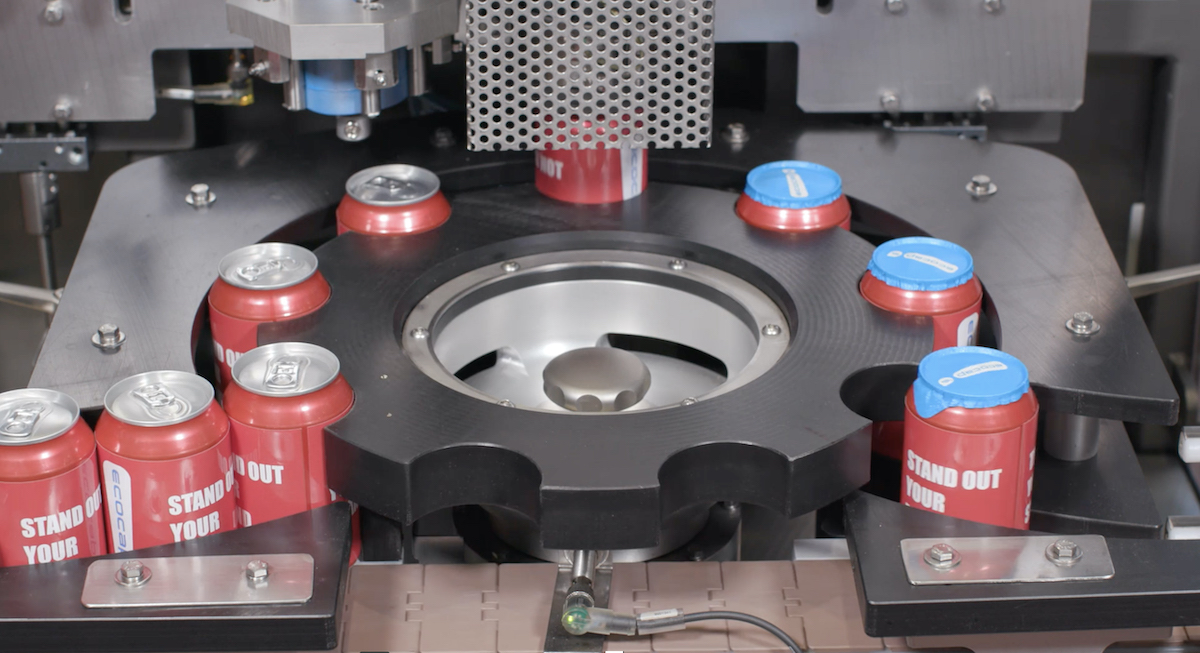

“This solution allows the aluminum cover to stay firmly attached to the can thanks to a stronger sealing that reinforces the point of attachment to the top: it increases its strength and prevents the consumer from easily removing TopSyl and tossing it on the ground.” Explains Cassoli, this requirement comes from customers, who request conformity to the environmental standard for closures tethered to the container."

Ecocap’s is now focused on perfecting automation that will align the flap of the top to the opening of the can. “This would enable the consumer to open Topsyl partially, making it easier to use the can – but it’s no easy task. No one has ever done this before, and there are technical difficulties to overcome.”

The main challenge is how to orient the can, that is, to rotate it in the right direction and then apply Topsyl. Graphics cannot be used as a reference since they aren’t positioned with the opening. In addition, the machines for applying TopSyl operate at very high speeds (up to 1,250 cans a minute). “Orientation systems are now in place in the final phase of multipack packaging,” says Cassoli, “and are able to align the graphics of the cans so that they are all pointed in the same direction; however, operating on multiple rows they have much lower speeds. The eventual solution also has to be applicable to pre-existing machines, and most importantly have an acceptable cost; otherwise the market is going to reject it.”

In the meantime, how was the new product received at the fair? “The number of contacts was positive to be sure, but there was little follow-up. Of course, the times we’re in don’t help and have induced companies to review their budgets. The orders are there, but installations are postponed to late 2023, and for operating machines even the next season.”

The market of reference for Ecocap’s is the Middle East (Turkey, Israel, Saudi Arabia and Egypt). “Our regular customers have requested an additional machine to their line, which proves the validity of the product. The Saudi market, which started up last year with Coca-Cola, is seeing its numbers grow and requests from local companies.”

How about Europe? “The situation is different, especially in Italy, where certain preconceptions are hard to break. Large-scale distribution puts a barrier to this solution: since it is not supported by demand from consumers, it isn’t willing to incorporate the cost into the sale price.” This invites a broader discussion on packaging in general and the willingness of large-scale distribution to recognize and sustain the environmental and economic value of innovations, regardless of consumer demand, making it an actual vehicle for promoting sustainability and food safety.