Topsyl guarantees the hygiene of can tops while offering a marketing feature that sets the brand apart. These two advantages of the automatic machine+packaging system from Ecocap’s of the Cassoli Group motivated San Bernardo to install the system about a year ago for its brand of canned mineral water and canned soft drinks produced for other companies. Besides the safety, simplicity and contract formula of Ecocap’s, an important characteristic is sustainability: TopSyl stays firmly attached to the rim and is the same material as the aluminum can.

Partners

Montecristo Group founded by the Biella and Colombo families is a player on the market of mineral waters and soft drinks with its own brands, as well as co-packer and supplier of the private label. The group has over 300 product items in its portfolio.

It controls three companies with four production facilities: S.Bernardo (50% of turnover) with seven production lines distributed between the plants in Garessio and Ormea. The other two companies, Fonte Ilaria and Fonti di Posina, have three and four production lines respectively. The production of 800 million units including glass and PET bottles and aluminum cans generated a turnover of 180 million euros in 2022. The two main partners for bottling pants, Krones and Sidel, have now been added with a third, with one of the companies of the Cassoli Group which, with Ecocap’s, CPS and Nema Automazione, is specialized in automated systems for packaging mass market products.

Reasons behind the choice

In 2021, S.Bernardo decided to use the sleek aluminum can type to be more eco-friendly and to give the consumer an added choice: Antonio Biella, CEO of Gruppo Montecristo, prefaces by saying: “The historic trademark identifies a mineral water that is unique in its organoleptic characteristics, especially its lightness. We believe that customers and consumers should be able to choose among all possible sizes and materials based on their awareness. So, we now offer the aluminum can as a way to increase our range and meet the preference for a lightweight material that’s easy to sort and recycle.”

The value in marketing terms is the visual and tactile elegance of the can, its shape, and the sleek format suggestive of a glass. Using this logic, S.Bernardo introduced it to give an extra option to sales channels in their aim to support consumer preferences. This was their perspective when making the decision to adopt the TopSyl system of Ecocap’s, an automation in line with the bottling lines that applies and heat-seals an aluminum cap on can tops, with a flap to help lift it off but attached on the opposite side to respect the standards of the Tethered Caps directive.

Advantages

The two goals are to guarantee the hygiene of a premium product and to distinguish it from similar offers. “TopSyl recalls the flexible aluminum caps found on spumanti and high-end sparkling wine bottles,” - says Antonio Biella - It instinctively associates the product covered with TopSyl to that category of beverages. And this justifies the higher cost of the system compared to the can without it, and sets itself apart from other canned products not having it as well. Added to that, there’s the possibility to have limited editions or communicate sporting or business trade events with mineral water and products that we’re co-packers for, like Molecola.”

The perception of cost and value

The impact on TCO exists but is not decisive: these are mass market beverages, so even if the final cost to the consumer (who integrates these costs) is higher than that for water in a PET or glass bottle, and in the case of a soft drink higher than a mass-produced beverage, the difference in cost doesn’t shift the choice of the consumer towards something else. Out of S.Bernardo’s turnover, the incidence of cans is 3% including those produced as private label and third-party products. On the level of trade marketing, the aluminum can featuring TopSyl is highly appreciated in the hospitality industry, which S.Bernardo has chosen as the premium market of reference. But that does not mean that the values of elegance, safety and recyclability are not perceived by consumers of other channels. Molecola, for example, is also distributed in retail stores.

In-line management

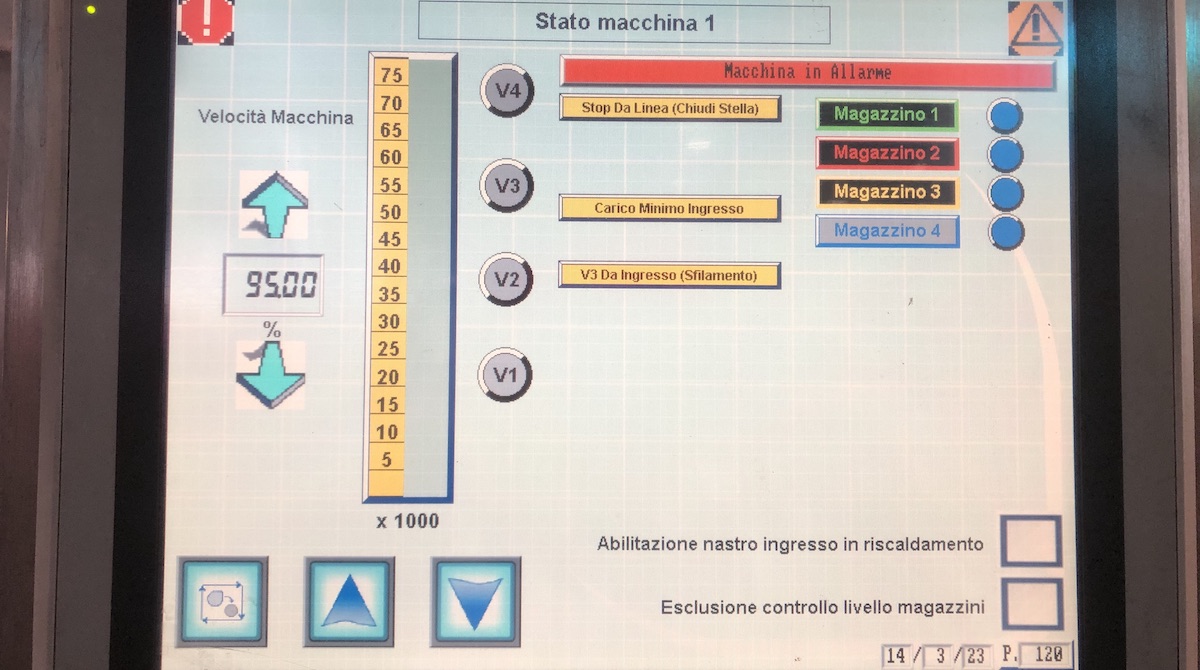

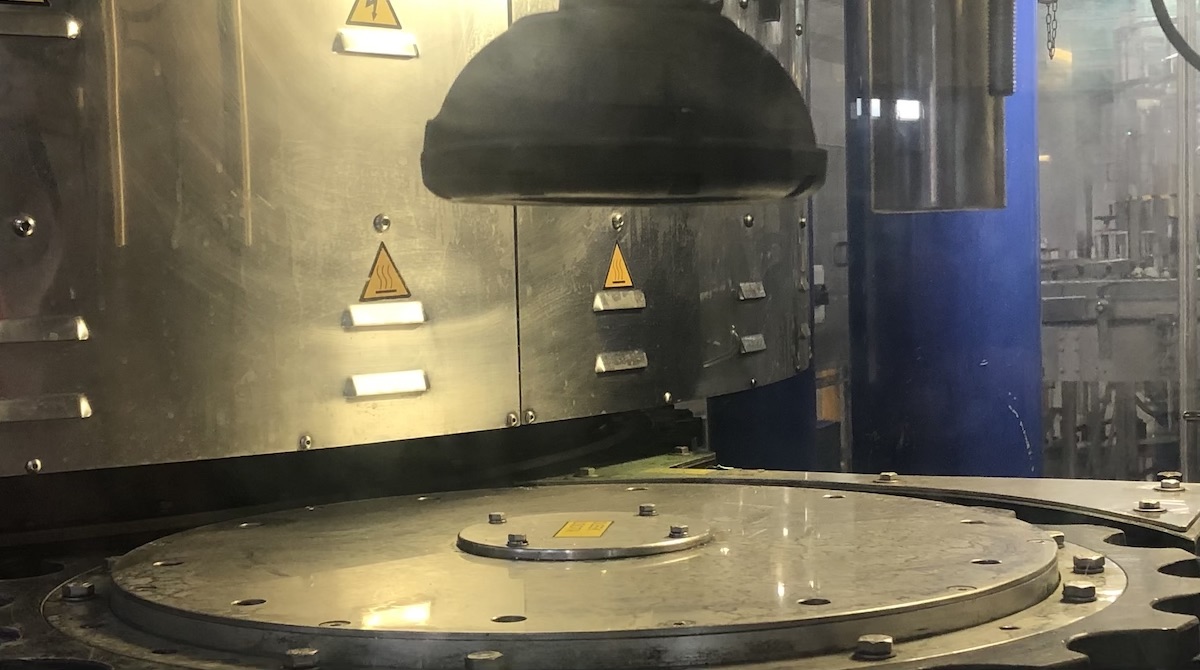

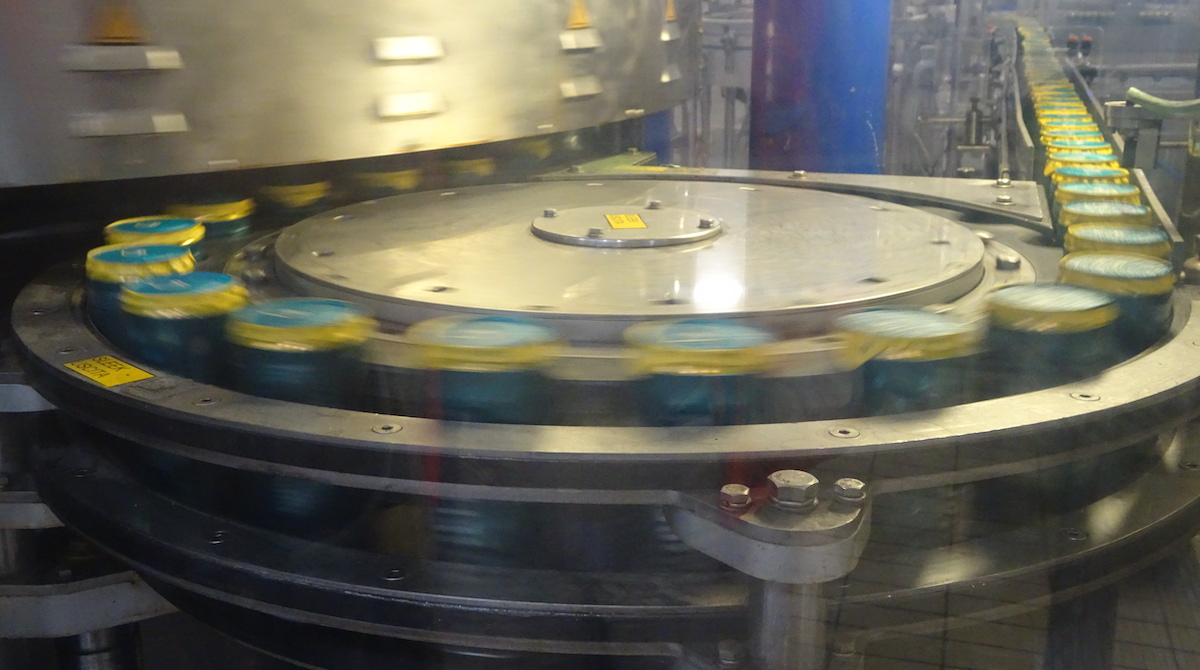

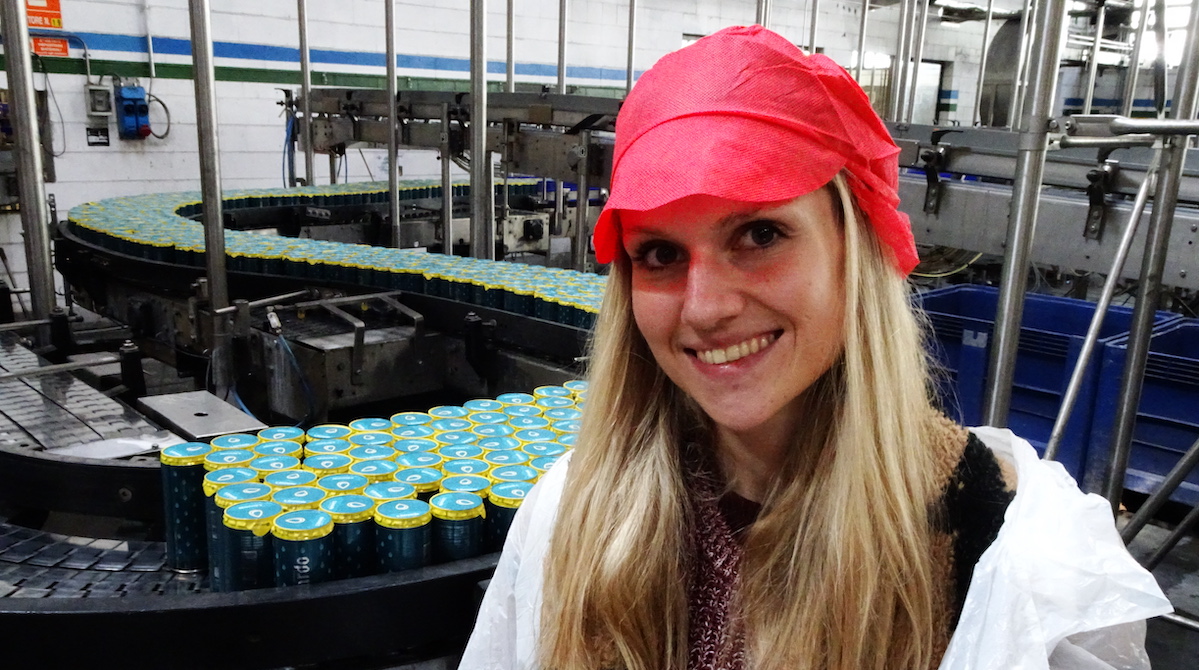

The machine that seals TopSyl to the cans is in operation at the Ormea plant near Garessio, where most of the production for third parties and private label takes place. Acquired via the rental formula (one of the formulas offered by Ecocap’s), it obliges S.Bernardo only to purchase the personalized caps. The rotary machine with 60 stations and an hourly productivity of 20,000 cans is placed at the end of the drying tunnel and, via a star wheel feeder takes them from the conveyor and applies TopSyl after heating to 200° C (melting the heat-sealing adhesive). The four loaders insert themselves into the boxes (containing the personalized caps delivered to the customer) and then onto the machine, with the camera controlling the presence of TopSyl. (Debora Raviola, Export Marketing Specialist with San Bernardo Spa.

Life Cycle Assessment

TopSyl is considered a sealing system and therefore subject to the European directive on Tethered Caps, which requires that the components stay attached to the packaging even after removing and lifting the flap from the can. Moreover, the cap is the same material as the can and so meets the requirements for recyclability. “It’s a system compatible with our goal to be ‘impact zero’ by 2026, which marks the 100th anniversary of S. Bernardo,” - explains Antonio Biella - Among the tools for reaching this objective involving all activities and resources, both materials and energy, we are also planning the LCA of various materials, shapes and sizes, including the can protected by TopSyl.”