In recent years, sustainability has grown from a mere trend to a strategic requirement for the packaging industry. With the introduction of regulations such as the Single-Use Plastics (SUP) Directive and the Packaging and Packaging Waste Regulation (PPWR), the European Union has outlined a development path based on circularity of resources, reduction of impacts, and responsibility of citizens and businesses in the packaging industry as well.

How is the market responding and, more importantly, what concrete solutions are sustainable product innovation-oriented companies like Giflor adopting around closure, dispensing and dosing systems for food and non-food products?

The SUP Directive challenge: less plastic, more innovation

Entering into force in Italy on January 14, 2022, The Single Use Plastic Directive aims to drastically reduce the use of single-use plastic products (such as plates, cutlery and polystyrene containers) an important contributor to marine pollution. Along the production, distribution and consumption chain, many companies have been forced to rethink their approach to packaging, introducing alternative solutions that meet new sustainability goals.

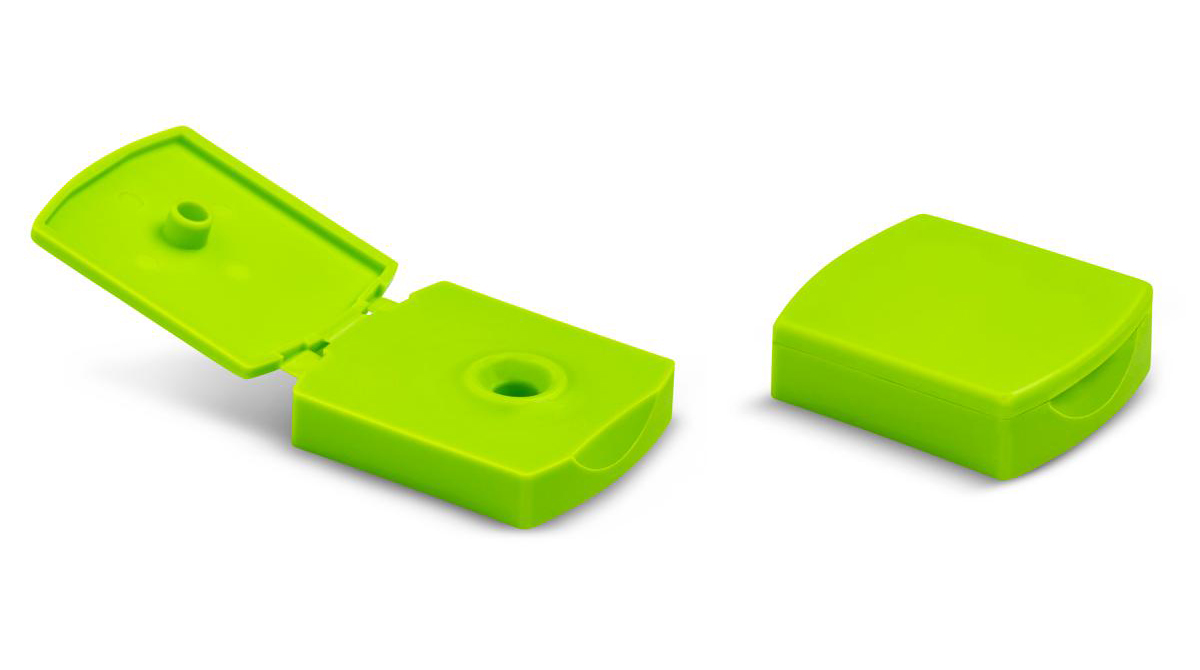

Giflor has been focusing on eco-design and intelligent use of materials since its establishment in 1973, and has responded to this challenge with a range of innovative products. The stars are Eco Low Profile (ELP) caps, developed to reduce the use of plastic by 50% compared to traditional caps, while maintaining high quality and performance. A concrete example of how material reduction can go hand in hand with efficiency and attention to design

PPWR regulation: recyclability and waste reduction as the new normal

As of December 2023, the PPWR Regulation introduced new standards for packaging management, requiring that by 2030 all packaging placed on the market be recyclable or reusable. This translates into a logistical and production challenge for companies and drives their growth.

Giflor, designs the lifecycle of products by adopting specific environmental paradigms: for example, mono-material caps and closures facilitate recyclability, reducing costs associated with disposal and promoting a circular economy. The ELP line not only reduces plastic consumption: all products in the line are designed to be easily recyclable, thanks to the use of mono-materials.

This first paradigm distinguishes Giflor in the markets as a benchmark in the industry: in 2021, the ELP cap for tube art. 772 won a gold award in the Tube Council's “Best Innovative Components or Processes” category, an award that celebrates the company's commitment to sustainable innovation. Over the years, other closures in the same line have received the same recognition from the U.S. association.

In addition, the upcoming Regulation now known in final draft as PPWR imposes limits on empty space in assembled packaging, pushing companies to optimize product dimensions. Giflor's Eco Low Profile Caps, through their compact design (the Vicenza-based company's second paradigm), make it possible to reduce the overall volume of packaging by 20%, with a positive impact on transportation and storage costs, (along with the third paradigm, the 50% reduction in plastic use compared to traditional caps).

The value of sustainable innovation: from PCR materials to iTap SOLO taps

Amid new regulations, innovation is not just a compliance issue, but a strategic lever. The adoption of recycled materials, such as PCR (Post-Consumer Recycled), is now an established practice at Giflor. The use of PCR polymers not only reduces dependence on virgin resources, but supports the circular economy. This fourth paradigm is not just about caps, but involves every aspect of production.

Another example of responsible innovation are iTap SOLO taps, Giflor's new brand, designed to prevent the release of microplastics into the environment (it's the fifth paradigm). Thanks to the unique tear-off opening system, the seal remains attached to the body of the dispenser, eliminating the risk of microplastics.

The packaging of the future is already here

New European regulations, such as the SUP directive and PPWR regulation, are steering the packaging industry toward paths of sustainability. For Giflor, this represents not only a challenge, but an opportunity to show that innovation and sustainability develop together. With products such as Eco Low Profile caps for bottles and tubes, the iTap SOLO tap, and an ongoing commitment to the circular economy, Giflor continues to be a best-practice example in the industry, demonstrating that the packaging of the future is already here.