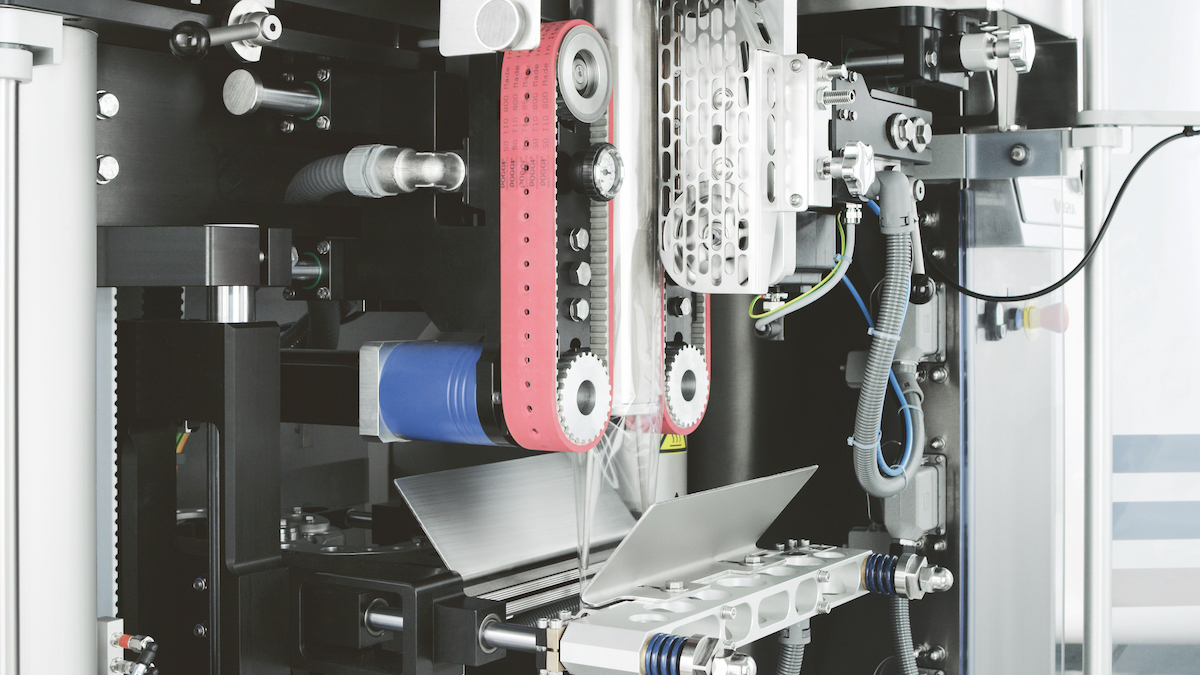

In the Foiano della Chiana plant, recently expanded up to 6,000 sqm, IMA Ilapak designs and builds VFFS vertical baggers and multi-head weighers. Various applications for food packaging are handled, with a dedicated focus on fresh and IQF products, such as cut salads, meat, frozen fish and vegetables, grated cheese and mozzarella balls.

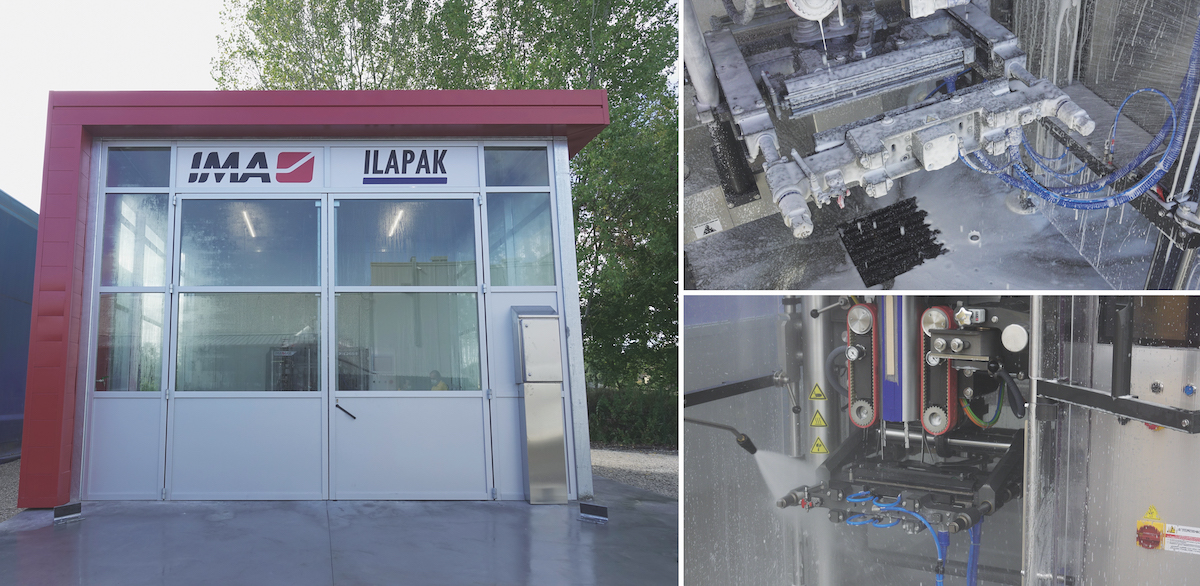

Ilapak Italia S.p.A.’s new manufacturing unit has been equipped with a ’cold-room’ able to simulate the production environments in which the machinery will operate and a room for high-pressure wash-down, specifically built to reproduce the customers’ sanitation procedures.

These rooms are an integral part of the OpenLab project, the IMA Group network of technological laboratories and testing area, dedicated to the research on sustainable materials, technologies and production optimization processes.

Since 2016, IMA Ilapak has checked the processability on its machines and analyses in the lab from 800 to 1000 film samples every year. Thanks to continuous research on materials composition and performance during the packaging process, our experts can identify the perfect match between machine and flexible film.

OpenLab is actively involved in studying most of the new sustainable and innovative materials even before they are commercially available. This allows us to test them in advance on the IMA Group machines and thus get valuable information on how to improve their performance. The major producers of the food industry and key packaging materials companies continuously cooperate with our lab to test new compostable, biodegradable, recyclable, paper-based or ultra-thin films.

New technical solutions have recently been implemented on IMA Ilapak machines aimed at minimizing the friction of paper-based materials with a barrier during the forming phase. Tests have shown the almost total absence of cracks even when using a paper with critical stiffness and sliding characteristics.

At the same time, new sealing systems are being tested with properties of elastic adaptation to the geometric of sealing area to avoid breakages and micro-fractures on new generation paper-based materials. This is essential especially for hermetic or modified atmosphere packaging equipped with barrier to gas/water vapor where even micro-leaks are very critical.

In this context, the developments carried out by IMA Ilapak for ultrasonic packaging are also included, where, with over 100 machines installed, the VFFS division is a key player in the fresh cut salad market. A technology that offers enormous economic and environmental savings thanks to reduction of waste: almost 25% less wrapping material in the environment and 30% less energy. IMA Ilapak, an analytical, empirical and technical consulting research approach aimed at promoting the use of sustainable materials while providing performing solutions.